iStock.com/OlenaMykhaylova

Cool beans

Innovative methods for preserving food are preventing spoilage and waste without sacrificing nutrition and taste.

One of the greatest challenges facing the world is producing (and distributing) enough nutritious and healthy food to feed, by 2050, an estimated population of 10 billion people. There are no simple solutions in the face of obstacles such as war, famine, drought, flooding, pestilence, and the myriad other things that make this challenge so daunting. High on the list of problems to solve is eliminating spoilage and waste in vegetable, dairy, and meat products. Finding better and more natural ways to preserve them is key.

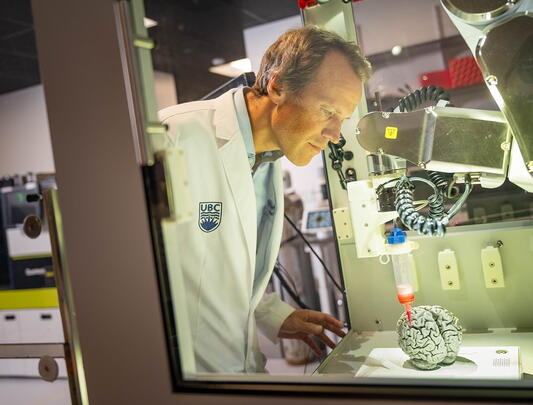

Mass commercial solutions developed in the last century rely heavily on chemical and thermal preservation processes, but these are notorious for degrading both flavour and nutrient availability. It’s not surprising that “processed food” has a negative connotation. Professor Anubhav Pratap-Singh and his team at UBC’s Food Process Engineering Laboratory (FPEL) want to change its image.

Pratap-Singh holds UBC’s first food and beverage innovation professorship and focuses on 21st century technologies that reduce waste and enhance the nutritional value and shelf life of processed foods. “We can achieve similar anti-microbial and anti-oxidization effects from more natural processing methods as we did with chemicals and high heat,” he says. “Technology is now eliminating artificial preservatives and chemicals from processed foods, as well as nutrient-destroying procedures such as high-temperature production methods.”

Preserving green beans (and other vegetables) is a good example of the use of fresh technologies. Traditionally, green beans are submitted to high heat for 45 minutes in the can to cook them and eliminate microbial issues. The FPEL lab has shown that Agitation Thermal Processing can achieve the same results in 10 to 15 minutes. The cans are routed through an agitation processor as they’re heated, which shakes them back and forth and side to side, distributing the heat more quickly and uniformly, and achieving the same level of microbial inactivation, with significantly less nutritional loss. As a bonus, the beans retain a fresher flavour and their natural colour.

Although producers must pay for additional equipment in their production line, their costs will ultimately go down because of shorter processing time and a smaller fuel bill for heating the vegetables.

“Technology is now eliminating artificial preservatives and chemicals from processed foods, as well as nutrient-destroying procedures such as high-temperature production methods.”

– Anubhav Pratap‑Singh

Another energy-saving development concerns the pasteurization of dairy products using ultrasonication and pulses of ultraviolet light. This process, referred to in the trade as PL+US (pulse light and ultrasound), subjects dairy products to bursts of UV light and 22 kHz sound frequency to achieve the same level of pasteurization as traditional high temperature processing, which often gives the milk product a cooked flavour. (By comparison, the ultrasound used to view a human fetus is set at 100 kHz sound frequency.)

These processes and others (see below) are revolutionizing food preservation methods, making food safer, longer-lasting, more flavourful and, most importantly, nutritionally superior to foods processed using traditional methods. As a result, food growers and processors are lining up to investigate these new methods as both cost-saving and product-enhancement opportunities.

Pratap-Singh will head up UBC’s Food and Beverage Innovation Centre, due to open in 2024. Working with industrial partners, local growers, the BC Food and Beverage Association, small-scale food processors, and B.C.’s ministry of agriculture, the centre will test innovative ways to preserve food, eliminate waste, and “upcycle” processing by-products to create new commercial opportunities.

It will provide state-of-the-art equipment to meet these goals. A high-pressure microwave vacuum dehydrator, a dry-freezing tunnel, a super-critical food extractor, and a fermentation setup will allow partners to process up to 100 kilograms of product per hour to test concepts on a commercial scale, and to use the UBC community to market-test the results.

Pratap-Singh stresses that the overall purpose of the centre and FPEL itself is to develop systems and procedures that ensure the safe and economical preservation of a variety of foodstuffs. And by focusing on the processes of production, he says, we can ensure that safe and healthy food is distributed to even the poorest areas of the globe, where access to quality nutrition can be a debilitating struggle. Once these processes are perfected, and when the technology for accomplishing them is established and easily replicated, they will have a profound effect on food production and distribution, and in turn on nutritional health.

Projects of the Food Process Engineering Laboratory

Tastier plant‑based protein

Traditional methods for incorporating various legumes into consumer products as part of their protein component – such as yogurt, milk, and meat substitutes – often produce off-flavours. High-heat steam processing can reduce the intensity of these off-flavours, but can add a cooked flavour, and many nutrients are simply washed away. The lab’s alternative is to use a vacuum microwave along with lactic acid fermentation to dehydrate the legumes without nutrient loss or impact on the flavour, and with increased digestibility due to fermentation. It also destroys harmful microbes. Incorporated into products like non-dairy yogurt, these proteins help to extend shelf life and increase consumer acceptance of plant-based foods.

Food packaging made from blueberries

Blueberries are renowned for their anti-oxidant and anti-microbial properties. During the processing of blueberries for juice and other uses, a pomace is extracted that contains a mixture of skins, seeds, and other by-products. When this pomace is blended and mixed with certain starches, it can be used as a wrapping material for fish and various vegetables, such as cucumbers. The anti-oxidant and anti-microbial properties of the blueberries remain in the wrapping, helping to protect and preserve the product it’s used to wrap. Because the wrapping is made from vegetative matter, it is entirely biodegradable.

Upcycling spent grain from breweries

Grains used in beer production – oats, wheat, barley, rice – produce a popular product, but once they’re used, most end up in the landfill. These “musts” are too microbially active to be used as feed or any other product, unless they can be pasteurized. The lab has developed a process that uses a vacuum microwave to dry out the grain in a low-thermal treatment that eliminates active microbes. It can then be made into fibre-rich and nutritious food products, such as animal feed – or tasty chips to consume with beer!

Naturally fresh fruit juice

Fruit juices have traditionally been processed using high heat as an anti-microbial fix, but this notoriously degrades flavour, appearance, and nutritional value. With watermelon juice, for instance, heat tends to flatten its unique flavour and causes it to change colour to an unappetizing grey. The chemical butylated hydroxytoluene (BHT) has been added to juices as an anti-oxidant to mitigate these problems, but that chemical has come under scrutiny as an allergen. Newer processes use natural acidification sources (such as lemon juice) and essential oils to preserve colour, flavour, and nutrition.