Changemakers

Reforming broken bonds

A new synthetic material could create longer-lasting products that “mend” themselves.

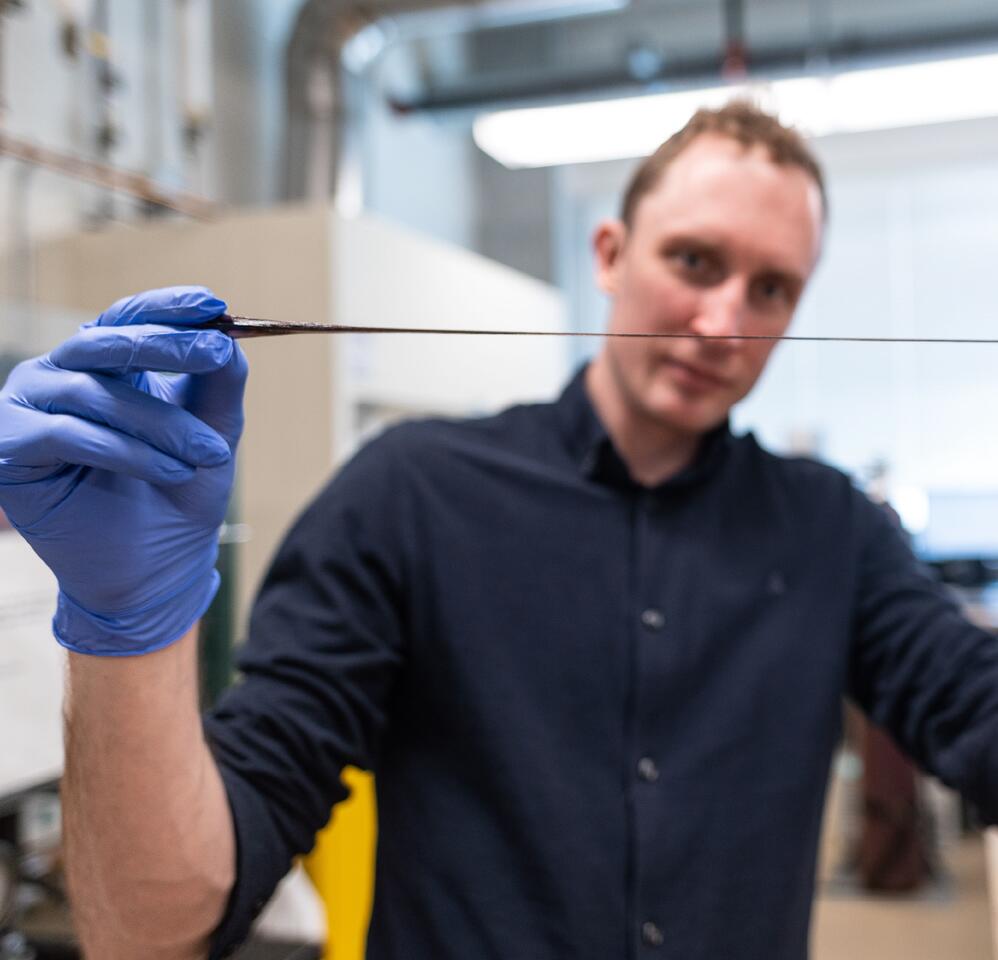

Damon Gilmour, co-founder of A2O Advanced Materials Inc. holding a piece of A2O’s self-healing polymer. Photo: Paul Joseph/UBC Applied Science

Imagine if the seams on your rain jacket, the paint on your car, or the coating on your smartphone could mend themselves after being ripped, scratched or chipped. This new reality is nigh – and it’s not as bizarre or science-fictitious as you might think.

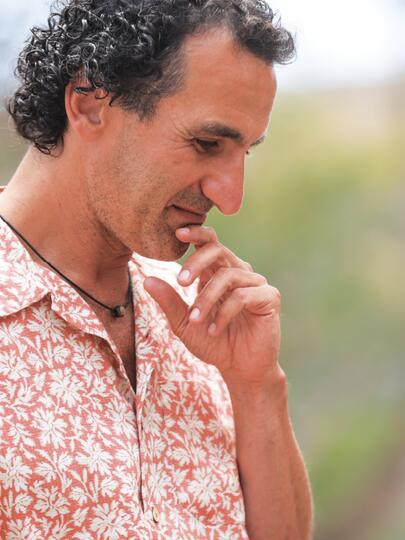

Damon Gilmour (PhD’19) and his company, A2O Advanced Materials, are developing a new class of self-healing materials that will extend the longevity of products and help slow down the damaging cycle of disposal and replacement.

Gilmour completed his doctorate in chemistry at UBC under the supervision of Professor Laurel Schafer. Through a collaboration with Professor Savvas Hatzikiriakos, they discovered new classes of aminated materials with unique physical properties, including self-healing and adhesion to non-stick materials. Recognizing commercialization as the best development option, they sought mentorship from entrepreneurship@UBC and cofounded A2O Advanced Materials in 2021.

The new materials respond to their environment with “dynamic behaviour.” When broken or damaged, they reform their bonds. Much like water, they possess hydrogen bonding, which drives forces of attraction between molecules. This bonding property can be observed when two water droplets, upon contact with one another, form one larger droplet. Gilmour’s team has harnessed this property into materials that can be used in better-performing films, coatings, or adhesives.

What’s more, the materials stick to everything — including surfaces with non-stick coatings. Gilmour envisions many potential applications. Paint used on boat hulls, for example, contains a biocide to prevent organisms (such as barnacles and seaweed) from accumulating, a problem known as biofouling. This creates extra drag, which means vessels dramatically increase emissions. Although the paint prevents biofouling, it simultaneously releases toxic chemicals into the oceans.

A2O’s new materials offer a more sustainable alternative to toxic paint. They can be used to attach a non-stick layer to hulls that repels ocean organisms. There isn’t any need for traditional adhesives – which usually fail underwater, less maintenance is required, and the coating can improve vessel efficiency to reduce emissions.

Although the efficient new coating promises to save money in the long-term, it requires scale-up to compete with the traditional products it seeks to replace. A longstanding emphasis on single-use and inexpensive materials has impeded industry innovation, Gilmour says. “If we don't invest in new materials, we're not going to have all the tools we need for our transition to a renewable energy future.”

While the company is working towards scaling up the technology, Gilmour says he has seen the shipping industry start to shift towards high-end products that can deliver both economic and environmental advantages. He hopes to develop more win-win applications for his sticky, self-healing materials. For the rest of us, that may mean better products, less expense, and a smaller environmental footprint.