Illustration by Andrea D’Aquino

Making petrochemicals... without the “petro”

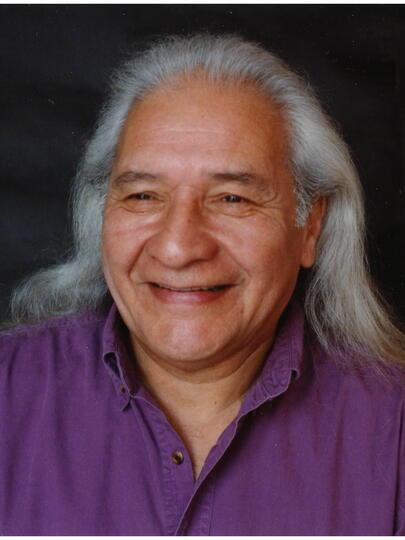

A UBC engineer is devoted to making our dirtiest chemicals clean.

What do you see when you think of a fossil fuel‑free society? Perhaps thousands of blue-grey solar panels, sprawled out among the corn and wheat fields? This postcard-worthy scene also springs to mind for Alexandra Tavasoli, assistant professor of mechanical engineering at UBC. But she thinks of a few other things, too: the massive amounts of coal used to make the silicon for the solar panels, and the tanker‑loads of petroleum used in the adhesives that hold them together. Even those fields of corn and wheat were probably grown with ammonia fertilizer – one of the most carbon‑intensive chemicals on the planet.

“Many of the chemicals that we currently make from fossil fuels – we actually need those chemicals to build renewable energy technologies,” explains Tavasoli. Even though generating electricity using renewable sources will significantly reduce CO2 emissions, simply investing in green power and driving electric cars “is not really a holistic picture of a truly sustainable economy,” she says. Countless cleaning products, soap and cosmetics, apparel, medicines, lubricants, solvents, and other products we rely on every day, either directly or indirectly, involve fossil fuel components and release vast amounts of carbon when they’re made. And if that knowledge makes you want a drink, we have more bad news: alcohol, too, has a massive fossil‑fuel footprint.

But Tavasoli has devoted her research to making the world’s dirtiest chemicals cleaner. Before she joined UBC, she was a postdoctoral associate at MIT and founded a startup that develops technology to manufacture chemicals using solar energy and carbon dioxide, instead of fossil fuels. Now, she leads UBC’s Laboratory of Future Industry (LoFI), where she and her team not only develop clean chemical manufacturing techniques, but also explore strategies for introducing those techniques into our existing economies and communities.

At LoFI, the team’s small‑scale reactors – festooned with tubes, electrical wires, and gauges – look more like they belong in the International Space Station than a commercial chemical plant. Yet these reactors can use the power of sunlight to convert CO2 and non-petroleum waste materials – including food waste, leftover wood from forestry, and even landfill garbage – into a huge variety of chemicals, including ethanol, hydrogen fuel, and ethylene for plastics. Theoretically, the reactors could be the key to low‑carbon chemical manufacturing.

... Theoretically. Making petroleum‑free chemicals in a lab is one thing, but incorporating that technology into our existing economy is another problem entirely. Tavasoli explains that when it comes to heating our homes and powering our cities, there are well-established, economically viable sources of clean energy that can be produced at scale (for example, the aforementioned sprawling solar farm). But the same can’t be said for many chemicals. “The path to commercialization isn't clear,” Tavasoli says. “You can't really take advantage of economies of scale the way a big, centralized petrochemical plant could.... There are just physical features of how the technology works that make it inherently uncompetitive against the fossil fuel status quo.”

One challenge is that the aforementioned alternative fuels, or “feedstocks,” are more distributed and vary in quality. Making chemicals using leftover twigs and branches from a nearby logging operation will never be as efficient as simply buying fossil fuels to use as a feedstock. “Even if you’re using all of the garbage at your region’s central landfill, the scale still pales in comparison to what fossil fuel facilities reach,” Tavasoli says. But clean hemical manufacturing doesn’t have to totally replace the traditional, dirty industry to make a difference. For example, a drugmaker could use clean technology to supplement its alcohol manufacturing. Or a farming community may use solar‑powered reactors to supplement its fertilizer production or serve as a backup if supply chains are disrupted.

LoFI’s ultimate goal is to write “how-to” guides to help communities discover opportunities to supplement fossil-fuel industries with clean alternatives using local waste materials or other resources that are already at their disposal.

Outside UBC, Tavasoli serves as board chair for Iron & Earth, a nonprofit established in 2016 by fossil fuel workers that encourages communities to free themselves from fossil fuels. Iron & Earth helps residents, businesspeople, and politicians explore ways to make their economies and infrastructure more sustainable and create job opportunities in green industries. Tavasoli and her colleagues may, for example, help local manufacturing plants source clean chemicals or advise city planners on adopting more efficient infrastructure.

But it will be a while before LoFI solar chemical reactors make it out of the lab. First, because Tavasoli has been at UBC for less than a year, and getting technology from the ivory halls of academia and into real‑world markets is a slow process. And, second, because society itself has some changing to do. Policymakers, businesspeople, and ordinary voters need to get used to the idea of a fossil-free economy in ways that go beyond installing solar panels and buying a Tesla. Tavasoli says that even if we could produce clean chemicals cheaply at scale, manufacturers would need to learn to incorporate new, clean adhesives into their products, or car companies would need to invest in hydrogen fuel cells. “The fossil supply chain is well organized and deeply ingrained in our economy, so to build out the green economy, you really need to build out the entire supply chain all at once,” Tavasoli said.

Yet parts of the supply chain are starting to change, here and there. More companies are adopting fossil‑free chemicals, if only at the margins. One distillery, The Air Company, has even started selling carbon-negative vodka made from water and CO2. Perhaps one day we will manage to create a society free of fossil fuels. And perhaps, the journey to that society has already begun, in Tavasoli’s lab.