Changemakers

Fantastic plastic

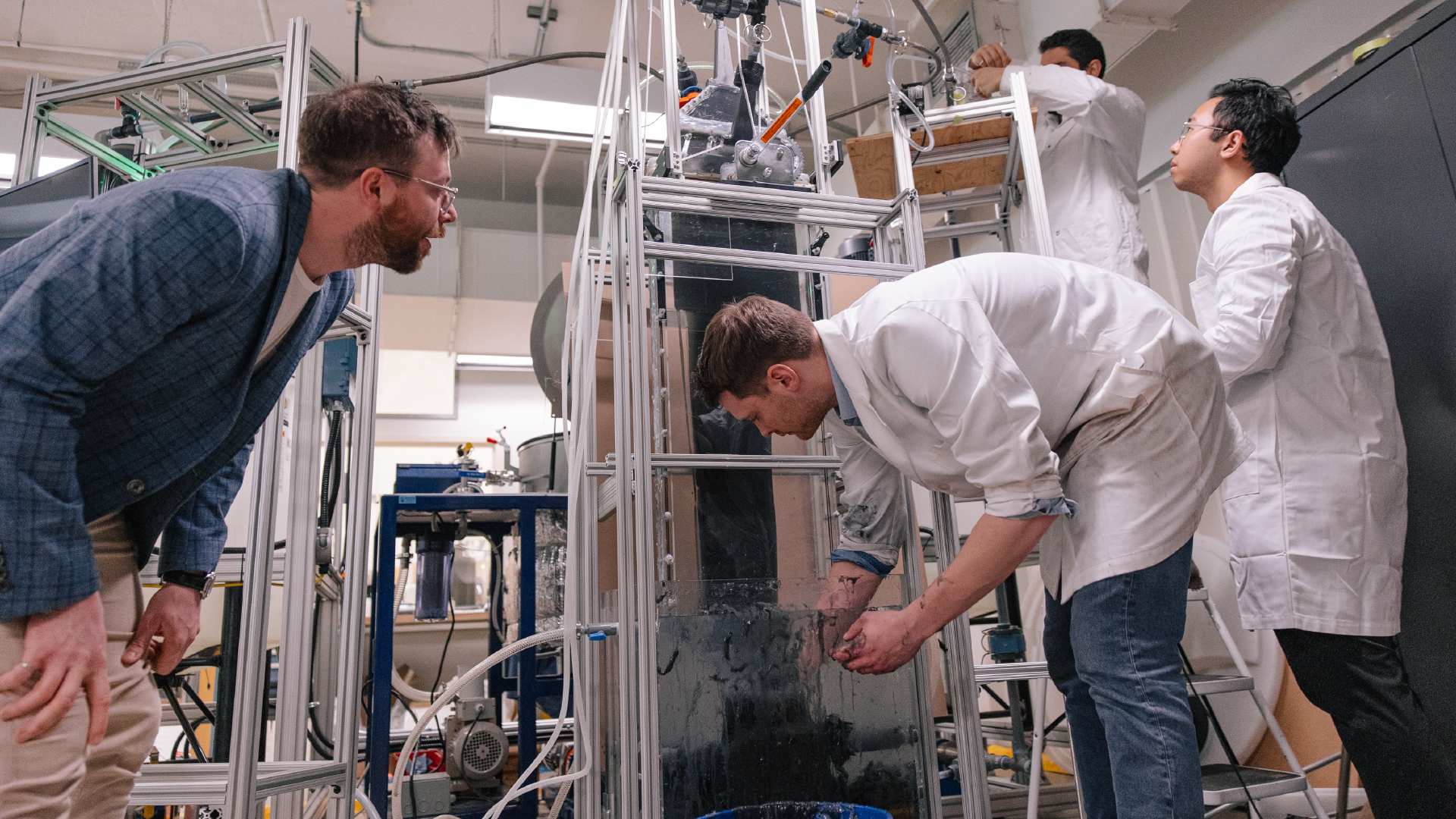

Jordan MacKenzie’s team has created a bio-based alternative to single-use plastic.

Jordan MacKenzie. Photography by Kai Jacobson

Any spare moment he gets, Jordan MacKenzie spends in the mountains around Vancouver. An avid hiker, rock climber, and skier, he’s witnessed up close the human impact on the wild places he loves: backcountry trails strewn with plastic, campsites left littered with waste. It’s a close-to-home glimpse of a staggering problem. The World Economic Forum estimates that we produce about 400 million tons of plastic waste globally each year. “That drives me nuts,” MacKenzie says.

What if we could eliminate single-use plastic altogether? It’s a question at the heart of Bioform Technologies, the business MacKenzie co-founded with UBC professor Mark Martinez to create a 100 per cent bio-based alternative to single-use plastic. Their patented biomaterial is inspired by spider silk and transforms wood fibre and kelp into a new kind of tissue that behaves like a sustainable version of plastic. Think compostable food packaging, water bottles, and cutlery. BioForm even makes their own mulch film, a replacement for the plastic sheets farmers use to protect crops. At the end of the season, instead of disposing of yards of plastic, farmers can simply plough the BioForm sheets back into the ground to nourish the soil.

MacKenzie’s vision for sustainability encompasses both the environmental and the economic. Most biomaterials are 3D-printed, a time-consuming process that also makes them expensive for consumers. So BioForm dreamed up a faster, cheaper process: “We wanted to run this as something as big and fast as an oil pipeline,” MacKenzie says. The solution lay in an old but efficient technology: Paper-making machines, adapted to “print” their signature wood and kelp blend. It’s a move rich in possibilities for Canadian rural economies. MacKenzie dreams of revitalizing towns where paper-making machines often sit idle today: “I really want to train personnel to start using this classical technology to produce a new product,” he says.

MacKenzie’s vision is big, but it took some time to get there. He and his teammates didn’t immediately realize just how transformative their new biomaterial could be. It was only through consultations with entrepreneurship@UBC that they realized the magnitude of what they had created – a real alternative to single-use plastics. The team’s original product was biomaterial tubing to help reduce medical waste from procedures such as dialysis or the use of IV drips. (The tubing also helped mitigate blood clots – nothing to sniff at, but no solution to a global environmental crisis, either.) To test the tubing’s properties, the lab workers were their own guinea pigs: “I think I donated blood a half-dozen times,” MacKenzie recalls. Ultimately, the tubing took a back seat – agriculture and consumer packaging offered more impactful ways to combat plastic waste – but with a team willing to literally give blood in the name of innovation, it’s little wonder they’ve found success.