Engineering at the Edge

It’s the stuff of nightmares, on an insidiously small scale. A relentless, indiscriminate villain attacks you at random, slashes your skin with a razor-sharp tube and uses it to suck up your blood. Then, adding injury to insult, it injects an Alien-like parasite (actually, a sporozoite) that proceeds to reproduce in your liver, thereafter wreaking physiological havoc and, in half a million cases a year, causing an excruciating, delirium-inducing death.

That may seem like a melodramatic description of malaria, but the mosquito-borne disease remains one of the top five killers in Africa. And if you’ve ever woken up in a Kenyan resort, feverish, nauseated, with a crushing ache in your neck and a feeling of ground glass in your eye sockets – well, you begin to take the very existence of the anopheles mosquito as a personal affront.

Yet, as everyone who has ever tried to sleep with one in the room can attest, even a single mosquito can be hard to kill. So it’s fabulous news that Dr. Kevin Golovin is working on an effective, affordable and environmentally benign way to make the wretched creatures simply go away.

Golovin is no bug doctor – not a biologist and certainly not an animal behaviourist. He’s an engineer with a specialty in materials science. Neither is there any formal singing in Golovin’s OPERA lab; the acronym stands for Okanagan Polymer Engineering Research and Applications. His focus there is on creating surfaces or coatings that repel ice, water and/or other liquids, or coatings that make boat hulls super slippery, so they use less energy to pass through the water.

Repelling mosquitos is a sideline, something Golovin stumbled into after having worked briefly as the vice president of technology for a US paint company. In Canada, he discovered an Ontario paint recycler called Loop, which was seeking useful applications for the surplus paint it collects. Loop was already working with a company called Kyzox, which produces rotundial, a mosquito repellent so powerful that if you pour some in a can of paint and then paint your house, mosquitos will avoid the place for years.

If you’ve ever woken up in a Kenyan resort, feverish, nauseated, with a crushing ache in your neck and a feeling of ground glass in your eye sockets – well, you begin to take the very existence of the anopheles mosquito as a personal affront.

While obnoxious to mosquitos, rotundial is not toxic to humans or other animals. It’s an extract from the vitex rotundifolia – better known as the roundleaf chastetree or the beach vitex, a weedy shrub native to seashores throughout the Pacific and currently raging as an invasive species along the southeast coast of the US.

The partnership between Loop and Kyzox clearly had great potential for helping vulnerable African villagers, but they didn’t know how much of the additive they needed to use, nor could they say categorically how long the amended paint might be effective as a repellent.

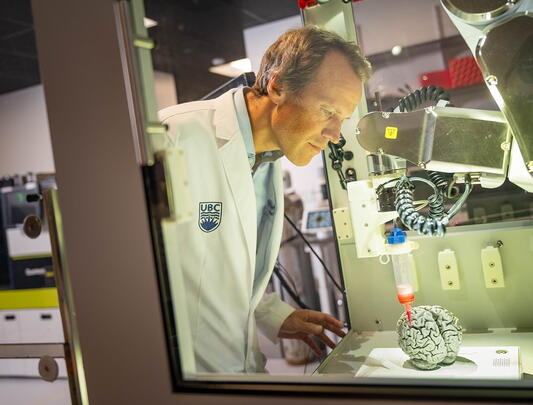

This, then, is the only imaginable circumstance in which you would be glad to live (or work) next to 10,000 mosquitos. One of Golovin’s academic colleagues at UBC Okanagan is Mark Rheault, a biologist and biochemist who has an insectary that is, in every literal way, swarming with research subjects. The buzzing hoards are managed, for this project, by a Brazilian graduate student named Letícia Recla – and as Brazil is ground zero for the devastating Zika virus (which is also mosquito-borne), Golovin says that Recla is “super motivated.”

Armed with a $100,000 Wall Solutions grant from the Peter Wall Institute for Advanced Studies, the scientists set about testing the paint solution’s limits and properties, and they found three things:

- Rotundial is a much more effective spacial repellent than N,N-Diethyl-meta-toluamide (DEET), which is the current industry standard for chasing off mosquitos;

- Only a small percentage of rotundial is needed in paint to make it effective as a repellent; and

- The paint can be designed to last for many years.

This means that you would be as safe inside a house painted with the rotundial mix as you would under a mosquito net – perhaps even safer, as no mosquito would be trying to slip through an accidental opening. Even better, Golovin says, if you could paint as much as 80 per cent of the buildings in a village, you could provide protection to the whole area – the mosquitos would simply clear off.

Looking at his whole body of work, Golovin appears to be developing a specialty of making things repellent to one another. Just as rotundial-infused paint repels mosquitos, Golovin is also looking for materials or coatings that repel everything from ice to oil, and there is a huge amount of interest in his research. For example, the clothing companies Arc'teryx and lululemon are supporting his experimentation in making textiles not just hydrophobic but omniphobic.

Perhaps obviously, hydrophobic describes materials that repel water – a crucial characteristic in waterproof or water-resistant clothing. But the complication for water resistance is oil, especially the oils in human perspiration.

As Golovin explains it, most materials that naturally resist water are still likely to absorb oil or, at least, are vulnerable to the oil breaking down the water repellency. To counter this effect, almost everyone in the outerwear business (and other businesses, as well) has been using additive chemicals called perfluorocarbons to help make textiles omniphobic – which, in an engineering context, means repellent to many things.

Looking at his whole body of work, Golovin appears to be developing a specialty of making things repellent to one another. Just as rontundial-infused paint repels mosquitos, Golovin is also looking for materials or coatings that repel everything from ice to oil, and there is a huge amount of interest in his research.

The problem, here, is that perfluorocarbons don’t break down in nature, ever, and they bioaccumulate (for example, when fish eat something with perfluorocarbons in it and you eat the fish, it builds up – ultimately to a toxic level). From 2023, perfluorocarbons will be phased out, but so far no replacement product is available to keep us dry in the rain.

Golovin’s emerging solution is silicon based, but it requires molecules so small that, when applied to fabric, they don’t bridge or close the gaps between fibres. If they did, the surface would repel water and oil, but it wouldn’t breathe. We’d be just as well off going back to plastic or rubber rain gear. With Golovin’s coating, every individual fibre will be omniphobic, preserving breathability, providing water repellency and standing up through the course of a sweaty hike or a brush with oily dirt.

Interestingly, the perfluorocarbon issue is also relevant in paper coatings, such as the ones that prevent the oil from your French fries soaking through to your lap. Catalyst Paper, whose perfluorcarbon-based processes for creating omniphobic wrappers will be curtailed by the 2023 phase-out, is also supporting Golovin’s investigations.

In Golovin’s world, “almost every problem occurs at the interface,” where the properties of different surfaces interact. The OPERA lab is also researching, creating and testing surfaces that are icephobic – which has useful applications ranging from the de-icing of airplane wings to the easy removal of ice cubes from the trays in your freezer. Golovin says it’s all about “fracture mechanics.” This is well-travelled ground because, in the engineering world, there is a huge amount of interest in understanding when, where and how things break – usually because the aim is to make things that are strong and resilient.

Golovin, however, actually wants the interface to be brittle, so he and his team delve into the theories of fracture mechanics, “then we take the equations and reverse them.” This, he says, “is not overly complex,” before delving into another explanation that seems to belie his understanding of the word “complexity.” Golovin says there are two ways to make something icephobic: you either want a surface that is thick and rubbery, so ice can’t hold on when it flexes, a great solution for an ice-cube tray or a refrigerator seal; or you want a surface that is thin and hard, so it promotes cracks, a likely application for coatings on windmill blades or airplane wings.

In Golovin’s world, “almost every problem occurs at the interface,” where the properties of different surfaces interact.

Yet another interface issue arises when you’re trying to make boats (or even swimmers) slip more easily through the water. You might think that a super-smooth surface would be best, but water clings quite well to smooth surfaces, increasing the drag. It turns out that it’s better to create a rough surface that traps a layer of air, which then forms a permanent break between the water and the surface.

Golovin gives the example of kale, which is inclined to shine underwater precisely because it has trapped air on its leaves. Of course, if you make the surface too rough, then the roughness itself will induce drag. But if Golovin can find the sweet spot, it could save energy the world over as boat builders begin producing crafts that require less fuel to overcome resistance as they push through the water.

One last comment on working at the interface: Golovin himself happily treads the line between theory and practice. His father was a battery chemist – a pure scientist – and “I did engineering in spite of him,” Golovin says. Yet just as Golovin senior’s work in electrochemistry brought him frequently to wrestle with practical applications, Golovin says he now runs “a very experimental lab” where they do “just as much science as engineering.”

As someone who was born in Maple Ridge, but grew up and was educated in the US (Cornell for undergrad, University of Michigan for his PhD), he’s also full-on thrilled to have landed at UBC Okanagan. He has called it “the perfect storm of a school,” academically strong and globally reputable but also “like a start-up: super open to innovation.”